Senior Design Sponsored Project: External Bone Fixation Device

The University of Texas at Austin

November 2020 - May 2021

Collaborated with team and sponsor to create an external bone fixation device for Jones fractures.\

Consulted with 3 surgeons to determine current limitations and areas for improvement.

Created and compiled FEA testing results on >50 iterations of 3D models with varying parameters.

The final design produced a 300% increase in force generation with the same length reduction.

Performed physical testing of prototype in saw bone which validated simulation results within 5%.

*Cannot post information/images of our device yet because it is still being developed and worked on by our sponsor.

Skin-on-a-Chip Model for Assessing First Degree Burns

The University of Texas at Austin

August - December 2020

Collaborated with team members to evaluate current skin-on-a-chip models and determine improvements that could be made.

Combined these improvements with the components necessary to create a model that is best able to mimic first degree burns on a chip.

Created outline of what model would look like, including cells to be used, set up of the model, how the model would be created, and conditions and parts necessary for the model so that it can be recreated by others.

Filed disclosure form to the Office of Technology Commercialization at the University of Texas to apply for a patent.

Biodesign Project: Continuous Noise Inhibition Ear Plugs

The University of Texas at Austin

August - November 2020

Collaborated with a team of four to invent novel earplugs with continuous noise filtering up to 20 dB.

Conducted customer & stakeholder outreach of 150 individuals to determine current limitations.

Followed design process to create a 3D SolidWorks model of earplugs & conduct validation testing.

Assembled “works-like” physical prototype of device which filtered and decreased noise by 15 dB.

Achieved continuous noise inhibition with a peak reduction of 20% in SolidWorks model of device.

Goal for this project.

Background of our project.

Desired outcome of our project/model.

Demonstration of Novel Mechanism section of our device.

Physical “works-like” prototype for our device.

Physical “works-like” prototype for our device.

Device Design of our device.

Functionality and Mechanism of our device.

Materials to be used in our device.

Simulated 3D CAD SolidWorks prototype of our device.

Efficacy Testing of our device.

Final slide of the presentation of our device.

Results from testing of the 3D SolidWorks CAD model of our device.

Results from testing of the 3D SolidWorks CAD model of our device.

Overview of our skin-on-a-chip model for assessing first degree burns.

Our proposed model and how it is novel.

Cell lines used in our model.

Combined technology of our model.

Assembly process for our device/model.

Explanation of the microfluidic aspect of our device/model.

Explanation of the 3D Bioprinting aspect of our device/model.

Experimental setup to induce first degree burn to our model.

Method for validating the barrier function of our model.

Method for validating the capacitance and permeability of our model.

Method for validating the pH of our model.

Method for validating the cell viability and immune response of our model.

Potential applications for our model.

Marketability/plan for marketing our model.

Limitations of our model and how we overcame/mitigated them.

Lung-on-a-Chip “Mega-Chip” Model of Adenocarcinoma

The University of Texas at Austin

January - May 2020

Collaborated with team members to evaluate current lung-on-a-chip models and determine improvements that could be made.

Combined these improvements with the components necessary to create a model that best mimics adenocarcinoma on a chip.

Created outline of what model would look like, including cells to be used, set up of the model, and conditions and parts necessary for the model so that it can be recreated by others.

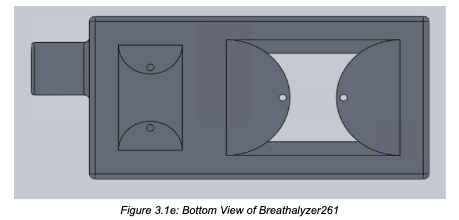

Breathalyzer Project

The University of Texas at Austin

January - May 2020

Collaborated with a group of four to design, simulate, & create a breathalyzer with 0.01% accuracy.

Generated Arduino IDE code to calculate concentrations of alcohol >25 ppm using an analog sensor.

Composed documentation to validate design and meet industry standards & regulatory requirements.

Engineering drawings of our device.

Cells to be used in model.

Engineering drawings of our device.

Cell morphology of cells in lungs.

Engineering drawings of our device.

Overview of the model setup.

Engineering drawings of our device.

Side view of our combined “mega-chip” model of the lung to model adenocarcinoma.

Engineering drawings of our device.

Top view of our combined “mega-chip” model of the lung to model adenocarcinoma.

Engineering drawings of our device.

Advantages and limitations of our model.

Engineering drawings of our device.

Overview of current models and their limitations, benefits our our proposed model, the potential impact it could have, and future improvements to our model or directions for future work.

ECG Device Project

The University of Texas at Austin

March - April 2018

Collaborated with a partner to create an ECG circuit, filtered and processed the signal in order to make it clear and easily readable, and soldered it into a breadboard for practical and easy use.

Carotid Artery Bifurcation Fluid Flow Analysis

The University of Texas at Austin

February - March 2018

Designed various specified bifurcation angles of the carotid artery on SolidWorks.

Conducted and analyzed a simulated fluid flow on each angle to evaluate different factors.

Compiled results to determine optimal design and reported results in a technical paper.

Final ECG circuit soldered into circuit board.

Fluid flow analysis of one of the bifurcation angles on SolidWorks.

Breadboard of working ECG circuit before soldering to actual circuit board.

Cut view of one of bifurcation angles designed on SolidWorks.

3D Printed Puzzlie Pieces

The University of Texas at Austin

January - March 2018

Designed an object on SolidWorks, 3D printed it, and reported the results in a technical memorandum.

Prosthetic Hand Creation & Demonstration

The University of Texas at Austin

October - December 2016

Designed and constructed a prototype prosthetic gripper in a group of three using given materials.

Programmed it to react to a motion sensor and perform various commands such as picking up a filled coffee cup and placing it back down, as well as doing the same with a raspberry without squishing it.

Reported methods and results in an oral presentation.

3D printed puzzle pieces fitting together in a cube.

Final prosthetic hand device.

Front view of 3D puzzle piece design on SolidWorks with dimensions.

LabVIEW code for prosthetic hand demonstration.

LabVIEW and Lego Two-Motor Car Simulation

The University of Texas at Austin

October - November 2016

Constructed a two-motor car using an NXT kit in a group of three, programmed it to perform a variety of tasks using various sensors, and then demonstrated the results in an oral presentation.

CControlled Release of Dye from Alginate Beads

T

September - October 2016

Coordinated with a group of three to facilitate and experiment to release water from beads of different sizes using a vacuum filter, a funnel, and filter paper.

Utilized a spectrophotometer to read a 96 well plate and then various results were recorded as plots to compare different aspects of the results, and then compiled into a lab report.

Final Lego Two-Motor Car.

Alginate bead controlled release results.

LabVIEW code for Lego Two-Motor Car.

Split times for alginate beads.